Simple to implement and operate, the 5000Q is also a uniquely compact, low cost, and efficient purge and pressurization system that allows you to save money and space with a solution specifically engineered for Zone 2 installations.

With a robust display screen and intuitive menus, the field-configurable 5000Q purge and pressurization system facilitates simple installation and safe, seamless operation of general purpose equipment, mounted in certified enclosures, within Zone 2, Zone 22 hazardous areas.

The 5000Q makes it easy to select the specific program to satisfy your application needs. Its compact size (122 mm x 120 mm x 90 mm) and easy-to-mount components make it simple to quickly mount it onto an existing enclosure, where an integral pressure sensor facilitates automatic purging and pressurization through the digital solenoid valve.

The 5000Q purge and pressurization system also allows the direct connection of PT100 RTD temperature sensors, which provide alarm contact outputs for user configurable set points. If the temperature exceeds these set points, the digital valve will activate to automatically cool the enclosure’s interior.

Suitable for a wide range of applications, purge and pressurization protection is one of the most flexible Ex protection solutions available. The principal behind a purge and pressurization system is to ensure that the inside of the enclosure is safe by keeping the corrosive, dusty, and potentially explosive atmosphere from penetrating the enclosure, by virtue of an overpressure within the enclosure.

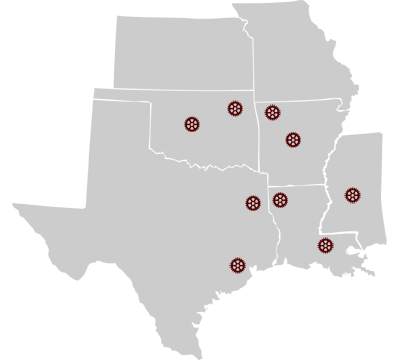

APPLICATION ASSISTANCE

The 5000Q Series Purge and Pressurization System is just one of the many offered by Pepperl+Fuchs and Industrial Electronic Supply (IES). We can assist you with selecting the right one for you by determining the following:

■ Area classification—Gas, Dust, Division 1 or Division 2, a particular Zone?

■ The often confused or overlooked gas group and temperature class.

■ Equipment ratings inside the enclosure.—Is there a containment system within the enclosure that houses a hazardous gas or liquid, for instance a gas analyzer?

■ Enclosure type and any specifics regarding doors, windows, and any accessories.

■ Power requirement to the equipment inside the enclosure.