The optimal use of data is becoming increasingly important for industry. Many companies are already analyzing machine and plant data on industrial PCs using their own software. Although this method delivers a great deal of valuable knowledge, it is resource-intensive and requires frequent manual updates to ensure that the software, operating system, and cybersecurity are always secure and up to date.

With Industrial Edge, everything is easier, more flexible, and more secure – for optimal use of data in the field. Acquire and process data directly and securely at the machine with no latency using your software and a central system for administration, deployment, and updates.

Cloud or Edge? Thanks to Industrial Edge, there is no need to choose.

You can have whatever you need.

Benefit from the best of both technologies!  With Industrial Edge, you enjoy all the benefits of edge and cloud computing – optimally tailored to your specific requirements. Industrial Edge allows you to analyze all the data at the machine and preprocess it instantly. The optimized data points can be transferred quickly to the cloud for more computing power and larger storage capacities. This allows for a precise analysis of data over longer periods of time. Based on your application, you decide whether and how you want to use the cloud in addition to Industrial Edge.

With Industrial Edge, you enjoy all the benefits of edge and cloud computing – optimally tailored to your specific requirements. Industrial Edge allows you to analyze all the data at the machine and preprocess it instantly. The optimized data points can be transferred quickly to the cloud for more computing power and larger storage capacities. This allows for a precise analysis of data over longer periods of time. Based on your application, you decide whether and how you want to use the cloud in addition to Industrial Edge.

Industrial Edge Benefits at a Glance

Conventional data processing on the field level is often costly and time-consuming, isn’t very scalable, and isn’t necessarily secure. In this case, Siemens starts with Industrial Edge and brings typical IT standards like central software management to the machine in a way that’s industry-compliant.

Enjoy the benefits of IT in automation technology in order to securely acquire and flexibly analyze your machine and plant data.

Constant software and operating system updates ensure a steady stream of innovations along with increased data security.

Platform functionalities like central updates, security, integrated connectivity, and integration into automation save time and money in software development as well as in operation.

Open standards like Docker offer you investment protection and a low initial barrier. In addition to Siemens, companies and programmers can also offer their expertise via the industrial App Store.

Edge Computing for Industrial Applications

How can we effectively integrate future-proof IT solutions into demanding OT environments?

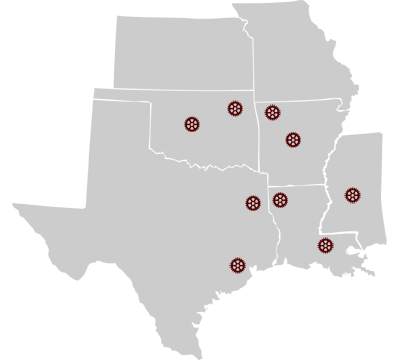

With Siemens high-performance Edge computing framework – combining the right hardware, software & end-to-end networking solutions designed for mission-critical industrial applications. By reducing computation times, Edge computing enables optimization across industries and helps close the gap between IT and OT.

With Siemens high-performance Edge computing framework – combining the right hardware, software & end-to-end networking solutions designed for mission-critical industrial applications. By reducing computation times, Edge computing enables optimization across industries and helps close the gap between IT and OT.

Future-proof your OT systems to gain a competitive advantage in your operations with customized, cost-effective, reliable, and scalable Edge computing solutions from a trusted partner.

Easy and stepless scalability

SIMATIC WinCC Unified enables you to scale easily and consistently for all your applications, from the operator panel on the machine itself to the complex SCADA solution. Thanks to flexible data exchange, the system simplifies the collaboration of all devices in the plant and enables authorized operators to access the system directly via any modern web browser – without having to install any separate plug-ins at all.

SIMATIC WinCC Unified enables you to scale easily and consistently for all your applications, from the operator panel on the machine itself to the complex SCADA solution. Thanks to flexible data exchange, the system simplifies the collaboration of all devices in the plant and enables authorized operators to access the system directly via any modern web browser – without having to install any separate plug-ins at all.

Transparency in Order Processing

SIMATIC Information Server

Full transparency of production data with web-based dashboards and reports

The SIMATIC Information Server gives you transparent access to plant information at any time. Historical plant data can be simply compiled in web-based dashboards or reports without programming knowledge. This ensures comprehensive access to plant information for each target group in the company (managers, quality assurance, maintenance) at all times.

The SIMATIC Information Server is a multi-system and multi-version reporting system for all corporate activities. Individually targeted reports and analyses can be created for historic plant data on a web basis and made available via dashboards. Access to these dashboards is also possible using tablet PCs. Predefined templates facilitate the creation of reports. This enables individual requirements to be taken into consideration by Microsoft Reporting Services. The creation and distribution of the reports may be time- or event-driven, e.g. as daily reports or shift reports. Various add-ins also enable the reports to be produced with Microsoft Office tools.

Bridging the Data Layer in Order Processing

WinCC/IndustrialDataBridge (IDB)

Flow of information between production and the IT world

WinCC/IndustrialDataBridge uses standard interfaces to connect the automation level (controls) with the IT world and to ensure a bidirectional flow of information.

Systems from different manufacturers can be integrated by using a variety of standard interfaces (e.g., OPC, OLE-DB, SQL).

The easy configuration (without programming) saves time and prevents errors. The integration into the WinCC system and its user administration as well as the alternative use as system service guarantee the security of the transmission.

- Connection of WinCC to databases and IT systems

- Cross-vendor support of standard interfaces (such as OPC, SQL, ODBC, OLE-DB, Office formats)

- High-performance, bidirectional data exchange between different systems

- Display of information on HTML pages

- Fast and reliable due to configuration instead of programming (errors are prevented)

- Application options:

- Start as system service for unmanned servers in computer centers

- For management of the RT data connections with WinCC

- Integrated management of connections during runtime in the WinCC user interface (also via web)

Get started today with Industrial Edge apps!

Get started today with Industrial Edge apps!

In addition to your own Edge apps or those from partner entities, you can also use data from your machines with Industrial Edge apps right away, with no need to do your own programming.

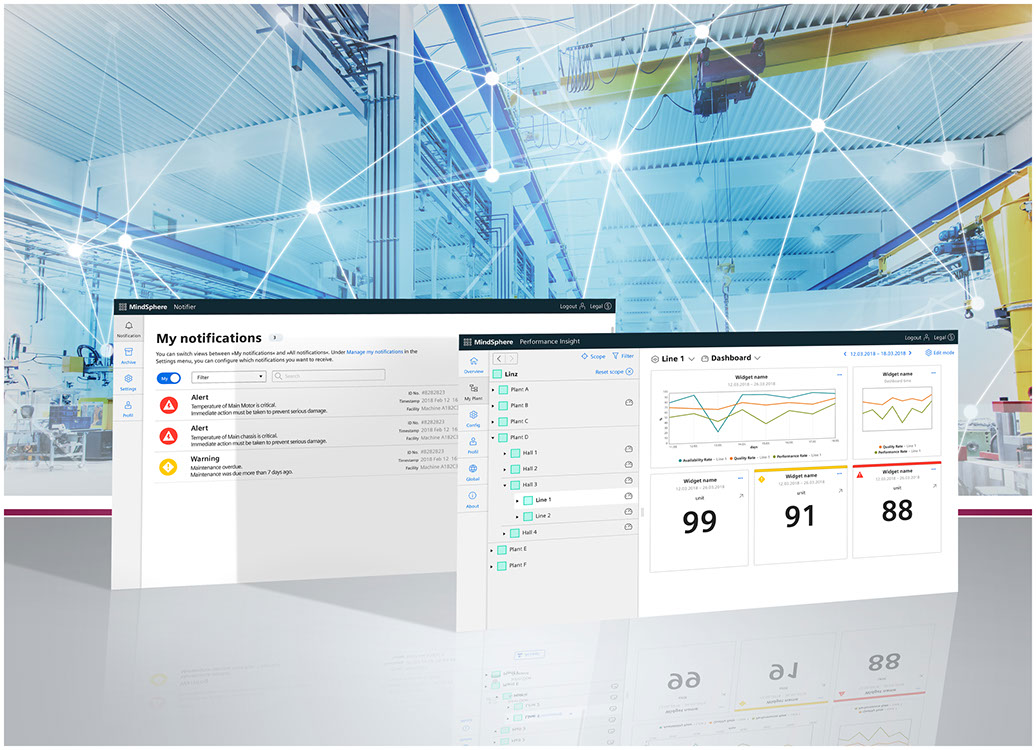

SIMATIC Performance Insight

The Edge app SIMATIC Performance Insight is the flexible tool you can use to monitor important KPIs for your machines, lines, and plant. Customized dashboards let you identify opportunities for optimization quickly and easily.

SIMATIC Machine Insight

You can use the Edge app SIMATIC Machine Insight to improve your machine maintenance and diagnostics. By observing diagnostic data, machine status, and alarms, you’ll find the underlying causes of problems in the easiest way and do a better job of targeting your service activities.

SIMATIC Flow Creator

The Edge app SIMATIC Flow Creator is the easy way to launch into data analysis. The graphic user interface helps you create individual data processing and connectivity solutions based on predefined functional modules.

With Industial Edge, everything is easier, faster, more flexible and secure, for optimal data use.